disc centrifuge|disc stack centrifuge working principle : factories CPS Instruments' Disc Centrifuge can be equipped with disc inserts that make it possible to change the centrifuge speed during a measurement without disrupting (mixing) the liquid in the rotating disc. Speed can be increased during analysis from below 1,800 RPM to as high as 24,000 RPM. This increases the practical dynamic size range (ratio of . 1. Autoclaving: This method uses high pressure and temperature (121°C for 15-20 minutes) to kill endospores. 2. Incineration: This involves burning the endospores, which is often used for .

{plog:ftitle_list}

HIV from contaminated materials may be slight compared with that of acquiring other blood- borne pathogens, such as hepatitis B virus, the effectiveness of disinfectants used under clinical .

yellow pipette tips price

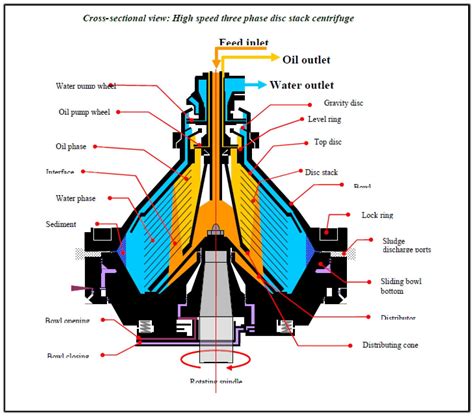

Learn how a disc stack centrifuge uses centrifugal force to separate liquids and solids with different densities. Find out how it differs from a settling tank and how it is used in various industries.Disc stack centrifuges are ideal for separating cells of the size 3–30 μm and culturing mediums having an initial cell concentration of 0.02–0.05%. In these systems, the centrifugal force is .

CPS Instruments' Disc Centrifuge can be equipped with disc inserts that make it possible to change the centrifuge speed during a measurement without disrupting (mixing) the liquid in the rotating disc. Speed can be increased during analysis from below 1,800 RPM to as high as 24,000 RPM. This increases the practical dynamic size range (ratio of .CentraSep DX disc stack centrifuges have two top outlets (labeled #6 and #7 in the following diagram) and a separate solids collection and discharge at the bottom (labeled #9). With three discharge points, you can have continuous .The disc stack centrifuge is used to remove solids phase from liquid, or to separate two liquid phases from each other by means of an enormously high centrifugal force, which is higher than 10,000g in most cases.. The denser solids or liquids which are subjected to these forces move outwards towards the rotating bowl wall while the less dense fluids move towards the centre.Disc Centrifuge – Particle Separation Efficiency. A disc centrifuge can separate metal particles down to a 0.5-micron level and Organic and inorganic particles down to a 1-micron level based on OEM data. These separations are dependent on the fluid being processed, specifically the viscosity of the process fluid.

yellow tips pipette

Whether in the mobile version or used as a stationary system: Disc stack centrifuges by MKR clean metalworking fluids, cutting oils and washing media in bypass mode during on-going operations. The respective process medium is pumped from the machine tank and is then pumped through a centrifuge. The cleaned liquid, from which particles and tramp . Disc Centrifuge is an efficient solid-liquid or liquid-liquid separation device that uses the centrifugal force generated by high-speed rotation to achieve the separation of materials. Compared with traditional centrifuges, disc centrifuges have higher processing capacity, faster separation speed, and better separation effect. The Disc Centrifuge Photosedimentometer (BI-DCP) and X-ray Disc Centrifuge (BI-XDC) are two unique technologies that offer high resolution particle sizing capability based on this principle. In both cases the difference in hydrodynamics between particles of different sizes drives separation, while detection based on the Lambert Beer Law allows . Disc Stack Centrifuges are incredible pieces of industrial equipment that have revolutionized the way we separate different substances efficiently. In this comprehensive guide, we will delve into the intricate details of how a Disc Stack Centrifuge works and why it has become an essential tool in numerous industries.

Disc Centrifuge Relevance: Back-Pressure : As discussed in the ‘paring disc’ section above, the liquid phases are pumped out under pressure from the centrifuge bowl through a paring disc pump. Throttling the liquid outlet exerts back pressure on the exiting fluid stream. Back-pressure on the liquid outlet ensures that the paring disc .The Disc Centrifuge Control System (DCCS) software, which runs on a personal computer, handles all data collection and analysis, and also sets the speed of rotation for the disc based upon the type material being analyzed and the range of sizes being measured. All distributions are recorded on a hard disc in the personal computer for

AlfaLaval–discstackseparatortechnology5 Insertingspecialplates(the“disc stack”)providesadditionalsurface settlingarea,whichcontributesto speedinguptheseparationprocessZK disc stack centrifuge product line is very rich, including DBY260, DBY350, DBY400, DBY470, DBY550, DBY640, DBY730 and other models of ordinary type, food grade and explosion-proof grade and other series to meet the needs of customers in different fields . Each of our product series adopts a unique design and is equipped with an automatic .Reconditioned Westfalia RSA 80 disc centrifuge. Model RSA80-01-076 3-phase 16,000 liters/hr (70 gpm) 4500 rpm 30.5″ bowl diameter SO RCF (g force) = 8785 New 480 volt motor – direct drive Bowl insertion tools, water harness, control panel with VFD and programming NEMA 4 Carbon steel skid for mounting machine, water harness, control panel. .Used Alfa Laval MAPX-207 Stainless Steel Automatic Disc Centrifuge Manufacturer: Alfa Laval Model: MAPX-207-SGT-29 Additional information: automatic desludging disc centrifuge, 3-way separator design, driven by a 7.5 hp motor, 460 volt, 1755 rpm. Location: West Coast USA. Get a Quote View Details

Disc Centrifuge is a mechanical solid and liquid separator based on the principle of centrifugal sedimentation.. It is widely used for the continuous separation of liquids with density difference and solid-liquid mixture. The disc centrifuge features are high rotating speed, stable operation, fully closed design, low noise, and superior separation efficiency.The CPS disc centrifuge separates particles by size using centrifugal sedimentation in a liquid medium. The sedimentation is stabilized by a slight density gradient within the liquid. The particles sediment through the density gradient inside a transparent rotating disc, through which a .

The Canada three-phase disc centrifuge market is witnessing significant growth due to its diverse applications across various industries. One of the primary applications is in the food and .

BI-DCP High Resolution Disc Centrifuge Particle Size Analyzer. High-Resolution Particle Size Analysis . The Brookhaven BI-DCP Particle Size Analyzer is a digitally controlled, high-resolution, particle size distribution analyzer. It yields high-resolution results in the size range from 0.01 to 30 microns with typical analysis times ranging from .A disc centrifuge polishes off the remaining fine eggshell residue from the liquid eggs as a polishing step. The eggshell particles have high specific gravity and are therefore easily separated under the disc centrifuge’s high g-force. Egg Yolk Clarification ApplicationDisc Stack Centrifuge - Effect of Flow Rate on Centrate Clarity. Therefore, the operator can reduce the flow rate to achieve better results with the same centrifuge. From the above example, it is clear that a disc stack centrifuge's capacity varies .Disc centrifuges are flow-through type separation devices. The separated clean fluids discharge through different outlets from the centrifuge. A paring disc pump creates pressure, which causes the fluids to flow out. Intentional Creation of Backpressure.

A standard disc stack centrifuge constitutes a stainless steel bowl with some parts that are not stainless steel. A food-grade disc centrifuge is made entirely of stainless steel, specifically all wetted parts of 316 stainless steel. A food-grade centrifuge also has some design features that allow for ease of cleanup. Disc centrifuge is a mechanical filter based on the principle of centrifugal sedimentation. It is widely used for the continuous separation of liquids with density difference and solid-liquid mixture.Discharging disc stack centrifuge. Discharging disc stack centrifuges include a bowl with perforated holes that allow liquid to pass through the basket as it rotates. This prevents denser solids from passing through the holes. For example, washing machines are considered discharging disc stack centrifuges, allowing water to exit the bowl while .

Disc Nozzle Centrifuges are high-speed centrifuges used for continuous solid-liquid separation, where solids are discharged through multiple nozzles located around the drum. The disc stack inside the centrifuge increases the surface area for separation, making these machines highly efficient in handling slurries with fine particles. . The disc centrifuge induces sedimentation of particles in order of size, physically separating mixtures into different components. Planning a successful DCP experiment involves selecting an appropriate gradient and disc speed to achieve the desired level of separation in a reasonable measurement window, in this case a disc speed of 8000 rpm .

A handful of considerations have a big impact on centrifuge efficiency. Disc Stack Centrifuge Efficiency. A disc stack centrifuge’s efficiency is the centrifuge’s effectiveness in separating the different phases in the process fluid. The centrifuge parameter settings and process fluid properties impact centrifuge efficiency.

disc stack centrifuge working principle

disc stack centrifuge technology

disc stack centrifuge for sale

DLC Vet Pty Ltd is one of the largest and longest serving veterinarian equipment and consumables distributors in Australia and New Zealand. Along with our current product portfolio we are part of the Device Technologies group of .

disc centrifuge|disc stack centrifuge working principle